SAFETY AND TACTICAL MARKINGS

SAFETY

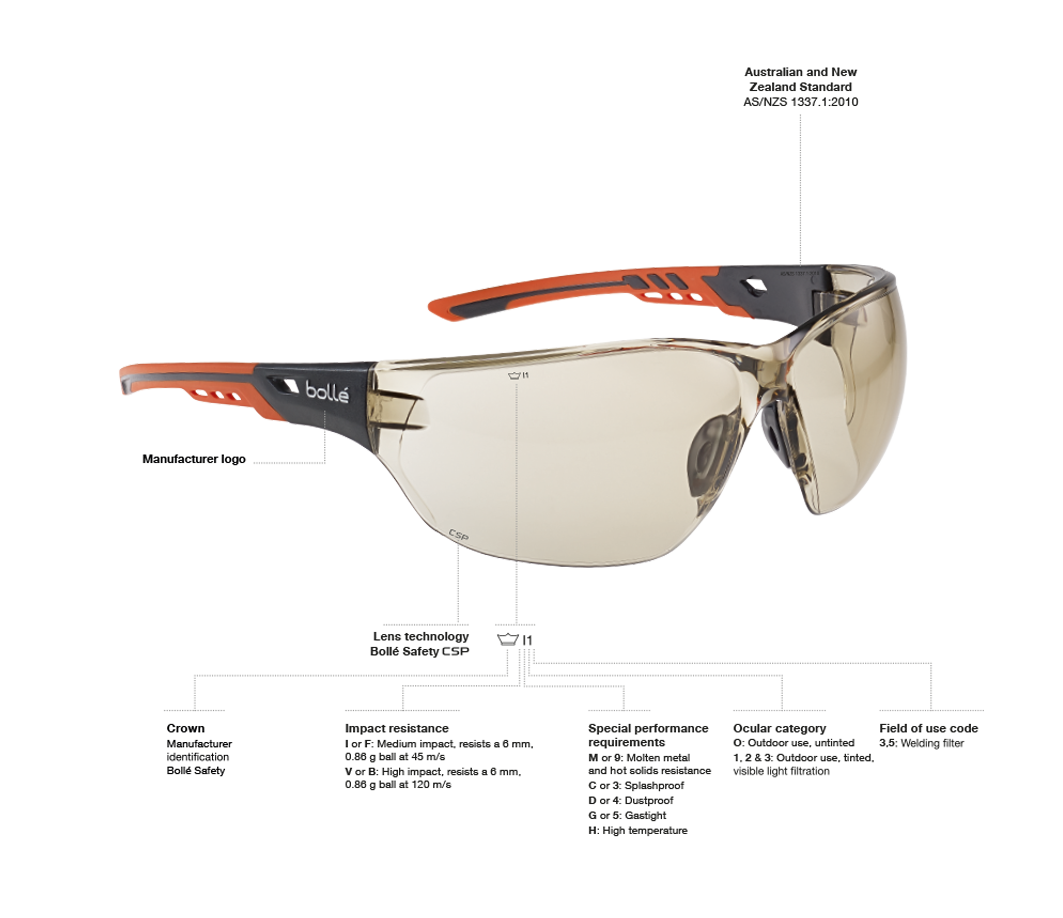

Bollé Safety lens and frame marking is specific to each product.

All safety eyewear in Australia and New Zealand requires certain frame and lens marking to show the spectacle conforms to AS/NZS 1337.1:2010 standards.This information helps guarantee the eyewear’s quality.

THE REFERENCE STANDARD

AS/NZS 1337.1:2010 Australia/New Zealand standard for personal eye and face protection for occupational applications. The AS/NZS 1337.1:2010 standard specifies minimum requirements for non-prescription eye and face protectors and associated oculars.

Standard AS/NZS 1337.1:2010 also defines the basic characteristics to which all eye protection must conform with regard to: eyewear coverage, optical quality and minimum strength.

While all eye protection must comply with AS/NZS 1337.1:2010, all filters and equipment are also covered by specific standards which must be understood in order to ensure protective equipment is adapted to the activity of its wearer.

The AS/NZS 1337.1:2010 standard applies to all eye protection and guarantees adequate marking and the quality of the equipment. Its purpose is to guarantee protection from:

- Impacts characterised by varying degrees of severity

- Flying particles and fragments

- Dust

- Splashing materials

- Molten metals

- Harmful gases

- Vapours and aerosols

- Or from any combination of these risks.

Bollé Safety designs and markets personal protective equipment for eye protection for industrial use consistent with the AS/NZS 1337.1:2010 standards. Each marking corresponds to a very specific use. All Bollé Safety products are tested at 23ºC and 60º C according to AS/NZS 1337.1:2010 standard. Tested by independent laboratories, certified by accredited bodies (BSI, SAI, Global and others), this information guarantees protective eyewear quality and resistance.

Bollé Safety strives to develop and provide high quality products with emphasis on health and safety of the customers. All Bollé Safety products are tested and approved to AS/NZS 1337.1:2010 for Medium Impact Protection.

LENS MARKINGS

Lens marking must include:

- The manufacturer's name or identification.

- Ocular marking.

- Other appropriate markings.

Impact resistance:

I or F. Medium energy impact, resists a 6 mm, ball at 45 m/s.

V or B. High energy impact, resists a 6 mm, ball at 120 m/s.

Special performance requirements:

C. Liquid droplets or splash resistance

D. Dust particles

G. Gas and fine dust particles

M. Molten metal and hot solids

FRAME MARKINGS

AS/NZS 1337.1:2010 Product had been tested and approved to Australian standards.

Bollé Safety’s environmental commitment:

Bollé Safety is committed to offering an alternative "environmentally responsible" option that is in tune with the needs of its customers.

In recent years, Bollé Safety now distributes its products in individual recyclable bags.

From manufacturing to logistics

All Bollé Safety products are subject to regulation REACH (Registration, Evaluation and Authorization of Chemicals), which ensures that all substances used on Bollé Safety products do not harm health or the environment.

TACTICAL

Products tested and certified

Bollé Safety Standard Issue designs and markets personal protective equipment for eye protection for industrial use consistent with the European Regulation 2016/425, and to the harmonized standard EN 166:2001.

Each Bollé Safety Standard Issue product is tested and certified by independent laboratories (Banc Officiel d'Epreuve Saint-Etienne, BSI, INSPEC, Certtotica etc..) According to European & Global standards.

STANAG 2920 & 4296

STANAG 2920

This standard concerns bulletproof materials and combat clothing. In the case of Bollé Safety Standard Issue, goggles and glasses are subjected to impact tests using projectiles simulating ballistic fragments.

All the tests allow to calculate a V50 corresponding to the speed at which the projectile has a 50% chance to perforate the material. The value of the V50 varies according to the nature of the materials and therefore the colour of the lenses.

STANAG 4296

The STANAG 4296 marking guarantees the ballistic resistance defined by STANAG 2920 but also incorporates certain use criteria (comfort, fog reduction, scratch resistance, etc.) and criteria relating to the general appearance (brightness, compatibility with other equipment, etc.).

MIL-PRF

MIL is an evolving American military standard: Mil - PRF - 31013 (1996) and Mil 43511D (2006) were replaced by GL-PD-10-12 (2010), which will then be revised and transformed into MIL-PRF-32432 in 2013.

These military standards specify criteria with which products must comply in terms of eye protection. These criteria concern in particular ballistic protection, optical qualities, product durability, etc.

The MIL standard which is used as a reference standard by many countries.