Our eyes are one of our most important organs but also one of our most fragile. Sight is arguably our most important sensory process, critical to navigating our modern lifestyles. We rely on sight when we walk and drive, when we read and write, and when we work and play.

There are increasing levels of exposure to heat and light, dust and chemicals, as well as biological contaminants in a wide variety of industrial and commercial workplace settings. These and other factors may lead to range of eye injuries, from simple eyestrain to severe eye damage making day-to-day activities more challenging or changing someone’s life completely.

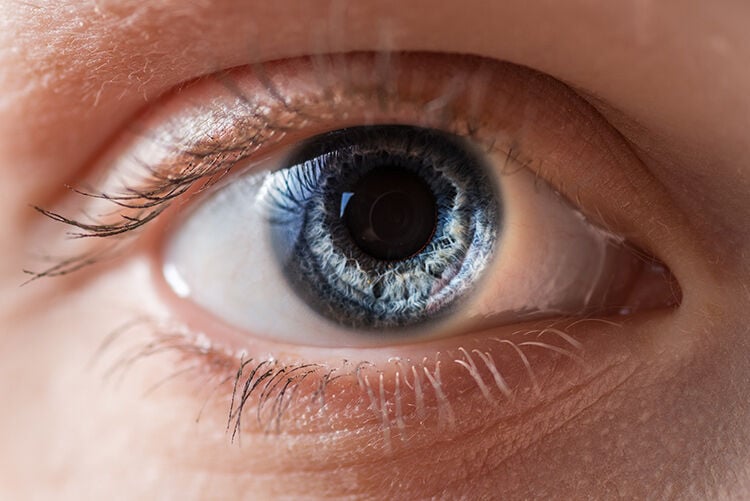

Our Fragile Eyes

Our sight is dependant on our eyes but they are only protected by a thin, transparent skin called the cornea. The cornea acts as a natural barrier against foreign particles and also plays an important role in vision - it is responsible for 65-75% of the eye’s total focusing power, according to the UK’s National Eye Institute.

The cornea and the lens, combine to focus light on the retina, a photo-sensitive tissue that surrounds the back of the eye. The retina then converts light into electrical impulses that are sent to the brain via the optic nerve, where they are interpreted as images.

Blue light can also damage the eye but a layer of pigmented cells known as the retinal pigment epithelium (RPE) nourishes retinal nerve tissue forming a pair of biological sunglasses that can absorb some blue and UV light. When the RPE is exposed to high levels or long periods of blue light, their ability to repair the damage is reduced, leaving the retina unprotected.

Types of Eye Risk

The eyes are vulnerable to a variety of hazards. Being made of soft tissue they are at risk of physical elements, especially sharp objects, and small particles. Their sensitivity to light is fundamental to sight but also makes them vulnerable to bright light and heat. In addition, their fragile moisture and pH balance mean that common chemicals found in a variety of different workplaces could cause serious harm.

Impact & Dust

The eyes are vulnerable to physical dangers such as sharp objects that could scratch or puncture the thin natural layer that protects the eye. This includes tools and materials that can pierce the eye. However, there is also a risk from small chips, fragments, particles, sand and dirt that may be made airborne through wind and other processes.

This small and potentially sharp particle may get caught in the eye causing punctures, abrasions and contusions of the cornea. In fact, corneal abrasions are the most common type of eye injury, especially in dusty environments. Damage to the eye may range from minor scratches that can heal in several days to more severe abrasions that can cause permanent damage.

The BLS found that almost 70% of the accidents studied resulted from flying or falling objects or sparks striking the eye. Injured workers estimated that nearly three-fifths of the objects were smaller than a pinhead. Most of the particles were said to be traveling faster than a hand-thrown object when the accident occurred.

Light & Heat

Our eyes are also sensitive to radiation in the form of light and heat. Burns can occur immediately or cumulatively when the eyes are exposed to bright light or high temperatures. This could be from fires, furnaces, welding torches, molten metal or sparks. “UV radiation in the 295-325nm range can cause photochemically induces opacities of the lens of the eye. Radiation above 315nm also causes cataracts,” says a 2016 study by Gregg M. Stave, Peter H. Wald.

Recent research has shown that high levels of blue light exposure can damage receptors in the eye and have a variety of implications for health and wellbeing. While the use of artificial light at night can trigger a variety of sleep problems, as well as physical, emotional issues. "Workers can even need protection against ordinary sunlight," Jim Johnson, CSP, safety manager for Black & Veatch highlights.

Chemical Exposure

The eye’s soft tissue is vulnerable to many chemicals that are common at home and in the workplace. Acids, alkalis, strong solvents and cleaning agents are now used in a variety of settings. Even a splash of bleach or a hairspray, for example, could have serious implications if it entered the eye.

Even short exposure to the mists, vapors and fumes of many industrial chemicals could be strong enough to cause irreversible eye damage. Contact with chemicals caused one fifth of eye injuries in the workplace, according to the BLS.

Workplace Hazards

Potential eye hazards are present in nearly every industry. Workplace eye injuries send 300,000 people to the ER each year in the US, according to the CDC. Eye injuries alone cost more than $300 million per year in lost production time, medical expenses and worker compensation in the U.S., reports the Occupational Safety and Health Administration (OSHA).

Construction

Constructions sites encompass many of the dangers listed above. Sharp tools and materials are everywhere, being used and moved in potentially unpredictable ways. Construction sites are extremely dusty environments with many forms of dangerous particulate matter. Mandatory use of hard hats help protect workers but for the best defence against workplace hazards eye protection is also essential.

“In construction, more than 10,600 eye injuries each year force workers to miss work. Construction has a much higher rate of eye injuries than any other industry,” says The Center for Construction Research and Training. While just over 20% of workplace eye injuries come from the construction sector, according to the BLS. "The [construction] work site itself is a hazard," claims Johnson, safety manager for Black & Veatch and a member of ASSE's Construction Practice Specialty Group.

Manufacturing

The manufacturing industry is broad and diverse but generally involves the assembly and finishing of physical products in the presence of human workers. Almost half the injured workers were employed in manufacturing in one way or another. While over 30% of the total eye injuries were working as operatives of assemblers, sanders, and grinding machines, according to the BLS.

The eyes of workers in manufacturing facilities may be at risk of impact by tools, machinery or materials. Factories can be full of dust and other particles that can be dangerous when in contact with eyes. There may also be harmful chemicals from the manufacturing or cleaning processes. While bright lights often bombard the eyes with harmful blue light frequencies for long hours.

Automotive

According to the BLS, more than 40% of workplace eye injuries occurred among craft workers, like mechanics, repairers, carpenters, and plumbers. A large section of this comes from automotive repair where welding, for example, can cause an acute condition called photokeratitis if the eyes are not protected. Not only are these workshops dangerous environments, they also have a reputation for a relaxed approach to eye safety.

“Many automotive mechanics are never taught the basics of safety,” says George Swartz, former safety director for Midas International. “Eye injuries may be the most common mishap in the business. Garages are often full of sparks flying from cutting torches and airborne pieces of metal launched from bench grinders, but most mechanics rely on nothing more than their eyelids for protection. A lot of guys just close their eyes while they're welding," continued Swartz.

Healthcare

Healthcare may not be the first industry you think of for eye injury hazards. However, healthcare facilities present the highest risks for viral and bacterial infections that can be caught through the eyes. Surgeons, who work with the open wounds of patients, already wear protective eyewear as a rule but this has not spread to other healthcare workers as much as the risk demands.

Healthcare workers are also exposed to bright lights for long hours as they go about their work. As discussed, the blue light frequencies emitted by bright lights and screens have serious short and long term implications for health. Be it for light or biological dangers, healthcare facilities like hospitals are dynamic environments where eye protection is important at all times.

Office

The key danger to the eye health of office workers is high levels of exposure to blue light. Time spent looking at screens, especially computer screen increases significantly in many office based professions. In many offices it has become normal for employees to spend their whole working day looking at computer screens.

Computer monitors and other electronic screens emit approximately 35% blue light, that’s 10% more than is emitted by the midday sun. Furthermore, many people now work on a computer, spend breaks on a smartphone, and the evening watching television. These high levels of exposure to blue light from screens can have serious and potentially irreversible impacts on eye and general health.

Protecting Eyes in the Workplace

While eyewear is a key element of protection when it comes to your vision, there are many other things you can do to ensure you are safe from potential hazards. Reducing hazards in the workplace is essential and there are tools made to help do so.

Reduce Hazards

Much can be done to reduce hazards in the workplace. All areas should be assessed for potential risks to eye health. Efforts should be made to reduce falling and flying debris, as well as smaller particles like chips and dust. Lighting should be adapted to better suit worker health and wellbeing. First-aid kits should be readily available, and eye wash stations should be carefully positioned around the facility. Eye safety policy, training and drills will help educate and reinforce eye health best-practice.

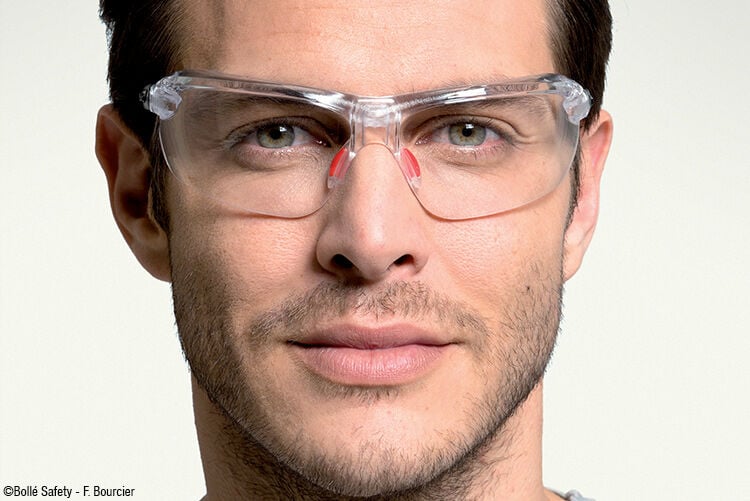

Protective Eyewear

Our better understanding of eye health is leading to stricter rules and standards within occupational health, namely the for the use of appropriate protective eyewear. This is for good reason, all the evidence suggests that glasses and goggles designed for specific workplaces, are the best way to protect eyes from the wide range of hazards.

An estimated 90% of eye injuries are preventable with the use of proper safety eyewear, according to the American Academy of Ophthalmology. While BLS reports that approximately three out of every five workers injured were either not wearing eye protection at the time of the accident or wearing the wrong kind of eye protection for the job. They also confirmed that more than 50% of workers injured while wearing eye protection thought the eyewear had minimized their injuries.

Some eyewear may protect against debris but dust and microscopic particles can also cause serious eye problems. “Safety goggles are the only effective type of eye protection from nuisance dust because they create a protective seal around the eyes,” according to OSHA. If dust is due to the nature of the work operation, then there will be continual exposure. If this is the case, workers need a goggle that will seal.

Safety First

Our eyes are fragile and our workplaces are becoming increasingly hazardous. Measures can and should be taken to reduce hazards in the workplace. However, to provide workers with the highest levels of safety at all times, employers must demand the appropriate forms of eye protection for the specific hazards of the workplace.

"As Ben Franklin once said, 'an ounce of prevention is worth a pound of cure,'" quoted ophthalmologist Anne Sumers, MD, clinical spokesperson for the American Academy of Ophthalmology. "It takes very little effort to protect yourself from on-the-job hazards that can cause blinding eye injuries. We strongly advise workers and their employers not to let their guard down when it comes to eye protection."